Categories

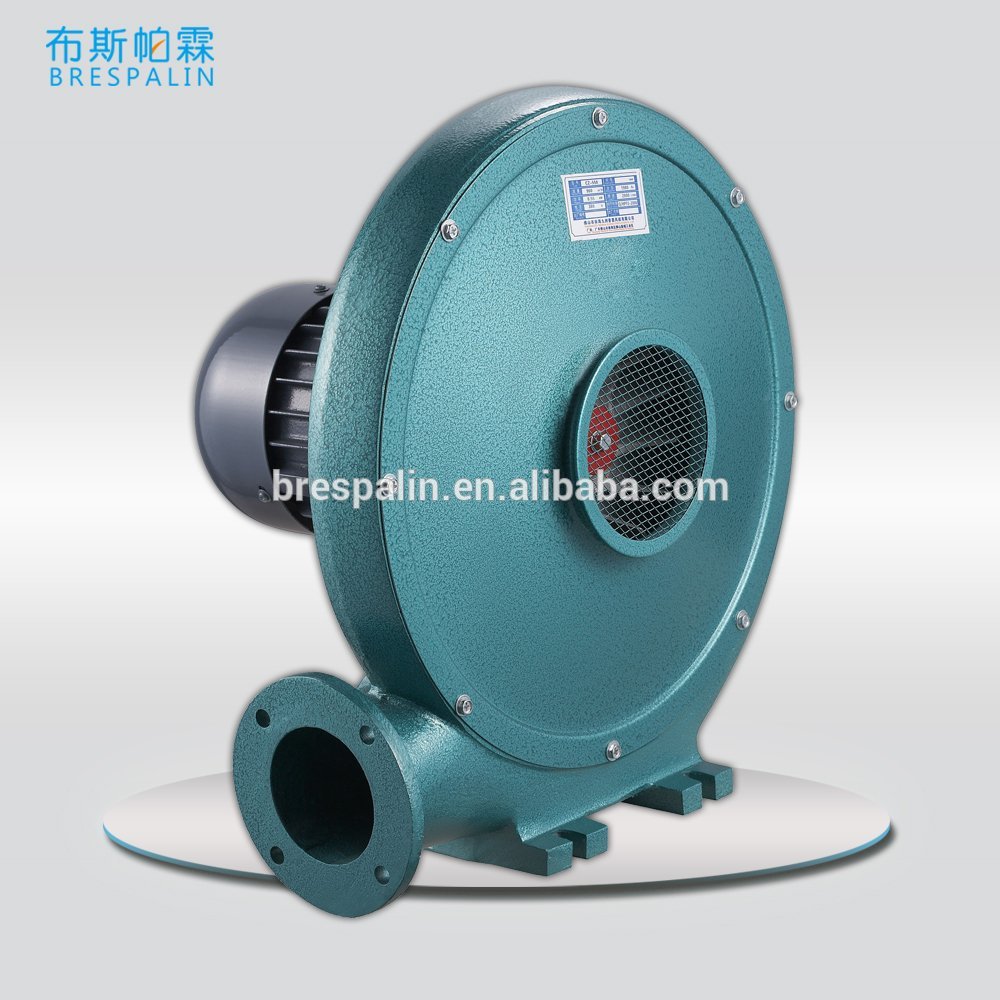

Chip Removal Industrial Centrifugal Fan for Air Suction and Powder Delivery

| Name: | Chip Removal Industrial Centrifugal Fan for Air Suction and Powder Delivery |

|---|---|

| SKU: | CZ-180W |

| Lead Time: | 3 days |

Product Description

| Iron Casing | Aluminum Casing | With Outlet flange, without base |

Multiple Industrial Use.

♦ Light

♦ Middle Pressure

♦ Large Air Volume

♦ Nice Appearance

♦ Low Noise

♦ Multiple Use.

Usage:

♦ Diesel vaporization heater

♦ Kitchen equipment

♦ Pneumatic Compression facilities

♦ Industrial Boiler

♦ Plastics production line

Working Conditions:

♦ Environment temperature shall not exceed 80°C

♦ Particles contained in the air shall not exceed 150mg/m³

♦ Air transferred shall not contain any toxic, corrosive and adhesive materials.

![]()

Specifications

| Model No. | Vol./Freq. (V/Hz) | Power (kW) | Rotation (RPM) | Air Volume (m3/h) | Total Pressure (Pa) |

| CZ-180W | 220/50 | 0.18 | 2800 | 408 | 1100 |

| 380/50 | 0.18 | 2800 | 408 | 1100 | |

| CZ-250W | 220/50 | 0.25 | 2800 | 450 | 1200 |

| 380/50 | 0.25 | 2800 | 450 | 1200 | |

| CZ-370W | 220/50 | 0.37 | 2800 | 690 | 1880 |

| 380/50 | 0.37 | 2800 | 690 | 1880 | |

| CZ-550W | 220/50 | 0.55 | 2800 | 960 | 1980 |

| 380/50 | 0.55 | 2800 | 960 | 1980 | |

| CZ-750W | 220/50 | 0.75 | 2800 | 1170 | 2140 |

| 380/50 | 0.75 | 2800 | 1170 | 2140 | |

| CZ-900W | 220/50 | 0.9 | 2800 | 1320 | 2140 |

| 380/50 | 0.9 | 2800 | 1320 | 2140 | |

| CZ-1100W | 220/50 | 1.1 | 2800 | 1404 | 2180 |

| 380/50 | 1.1 | 2800 | 1404 | 2180 | |

| CZ-1500W | 220/50 | 1.5 | 2800 | 1530 | 2400 |

| 380/50 | 1.5 | 2800 | 1530 | 2400 | |

| CZ-2200W | 220/50 | 2.2 | 2800 | 1560 | 2500 |

| 380/50 | 2.2 | 2800 | 1560 | 2500 | |

| CZ-3000W | 380/50 | 3 | 2800 | 1620 | 2650 |

![]()

Overall Dimension

![]()

Reassuring Service

We control every step of your order to make sure the goods arrive your side with good situation on time without any worry.

Strict testing for new products, OEM/ODM products, or customized products.

Strict testing for new products, OEM/ODM products, or customized products.

Our own molding factory (90T-1600T) provide us best cost, delivery time, quality for our Air Purifier, Anion generator, UV sterilizer, Fresh Air System, Exhaust Fan, Bathroom Fan, Heat Recovery Ventilator, Inline Duct Fan and so on.

Our own motor production line (two different department separated for different usage of motor.) provide us best cost, delivery time, quality for our own products.

Strictly required 5S workshop, regular staff training, in-process and final inspection, make sure every tiny mistake is stopped before delivery.

Specialized staff gives you an eye on your products. From our detailed loading report, you will know how are the products loaded. What you see will be what you received.

Company Information